Grasping the trend of the digital transformation period, in recent years, many coal enterprises have increased investment in high technology to improve productivity, “increase the power” of machinery and technology, reduce human resources, thereby minimizing the burden of costs.

Arriving at the mining area one day in mid-June, the hot and humid weather did not dampen the enthusiasm of the workers in this area.

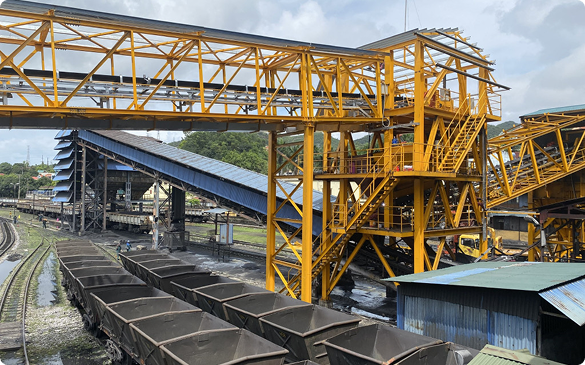

Receiving us in a very open and friendly atmosphere, Deputy Director of Vinacomin Machinery Manufacturing Joint Stock Company Tang Ba Khang said that in recent years, the company has increasingly focused on investing in installing modern equipment and production lines to gradually replace outdated machinery and equipment, reducing many cost burdens. Thereby improving the lives and income of workers.

Operating in the mechanical field, specializing in the production and supply of steel products, drill shafts… key products for coal mining, however, for a long time, Vinacomin Machinery Manufacturing Joint Stock Company had to import raw materials for production.

“Importing raw materials depends on partners, the cost is increased a lot, which are big disadvantages if we have to depend on imports,” Mr. Tang Ba Khang emphasized. Not to mention, old and outdated machinery and equipment reduce the competitiveness of enterprises.

However, the situation has now “turned around” – the deputy director happily said that since 2015, the company has put into operation a steel rolling line because the furnace with a capacity of 75,000-80,000 tons achieved a revenue of about 800 billion VND/year. By investing in new technology, the company has reduced many cost burdens such as reducing electricity loss, reducing raw material import costs, because according to Mr. Tang Ba Khang, the cost of importing raw materials to produce steel is very expensive, and depends a lot on exchange rate fluctuations.

Furthermore, when depending on imported raw materials, we cannot foresee the risks and unexpected events that may occur that impact the world market, thereby severely affecting the import of raw materials. The Covid-19 pandemic is an example. When the pandemic occurs, the import and export doors of the world market are narrowed, and of course, this severely affects customs clearance and import and export as we have witnessed.

“Although the initial investment capital was not small, more than 200 billion for a steel rolling line for the furnace, as soon as it went into production, this line proved its remarkable progress. Currently, from input to output, we are all operating in a closed production cycle, completely proactive in the raw material stage, and revenue has increased dramatically since 2015, the first year when this production line was put into operation,” said Mr. Khang.

Everyone knows very well that working in the field of mining, production and processing of coal products, if you stand still, it means falling behind. Understanding this factor, Nui Beo Coal Joint Stock Company (Quang Ninh) has proactively invested in modern equipment for mining at a depth of minus 350 m.

The company representative said that bringing machinery and exploration equipment down to a depth of minus 350 m is really not a simple thing. Previously, the deepest the coal industry could go was minus 300 m. However, with the investment in modern equipment and the solidification of basements with reinforced concrete, a new record for the coal industry was set when it reached minus 350 m. Welcoming us in miner uniforms, the miners were very enthusiastic.

Talking to us, Mr. Vi A Sinh (a miner from Lai Chau) said that although he knew this was a risky job, he still loved the job. “We miners receive very high salaries and good treatment” – Mr. Sinh said, adding that the current salary for miners is 18 million VND/month, while for “new recruits” like Mr. Sinh, the salary is about 15 million VND/month.