Coal dust

Product code: TC4A

With its small size, coal dust is easily used in many different combustion systems, especially industrial boilers and furnaces.

Advantages:

- Efficiency reaches about 90%.

- Heat loss to the environment: lower than other types of drying furnaces.

- High efficiency: because coal is cheaper, it leads to a reduction in input material costs, the cost of a manufactured product also decreases accordingly, helping to increase the competitiveness of businesses in the market.

APPLICATION OF COAL IN INDUSTRIAL PRODUCTION

1. Production of tunnel bricks

After arriving at the brick factories, the coal is fed into the coal crusher. The coal is finely ground and mixed with the brick-making soil on the forming line. The proportion of coal mixed into the soil accounts for about 70%-80% of the fuel needed to burn the product, the remaining 20%-30% of the fuel is sprinkled from the roof of the furnace to the brick stack on the firing cart.

2. Main fuel in boilers:

Boilers using coal as fuel to boil water to convert into steam are commonly used in industrial production industries such as food, textiles, animal feed, etc.

3. Providing energy for food drying ovens:

Coal-fired drying ovens are currently quite commonly used in drying products. Coal drying kilns can operate smoothly without much human control and have much higher capacity than kilns using other fuels. In addition, the use of coal drying kilns actually brings many economic benefits to the manufacturing industry, helping to save a lot of costs for businesses.

- Coal 4A1

- Coal 4A2

- Coal 4A3

- Coal 4A4

- Coal 4A5

- Coal 4A6

- Coal 4A7

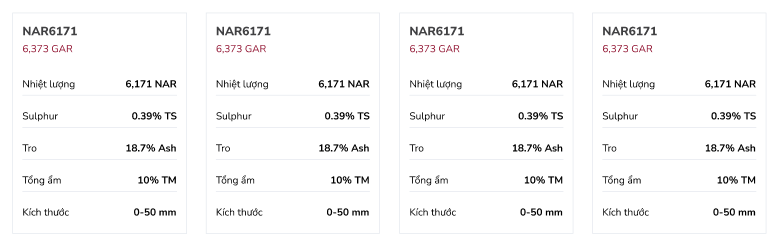

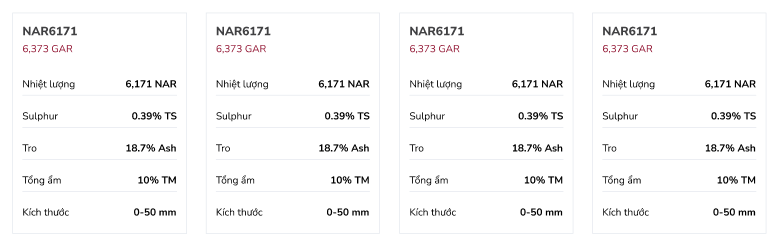

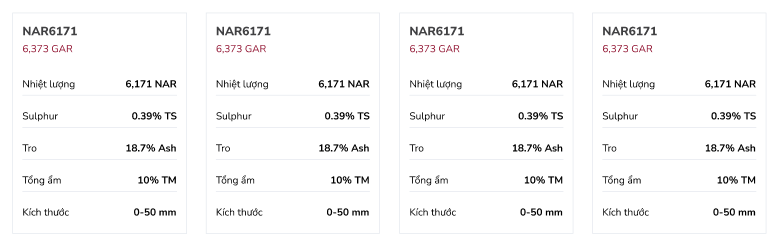

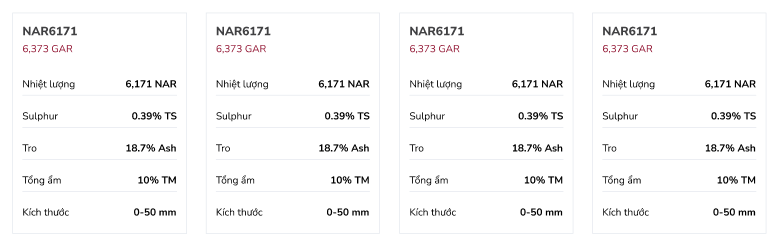

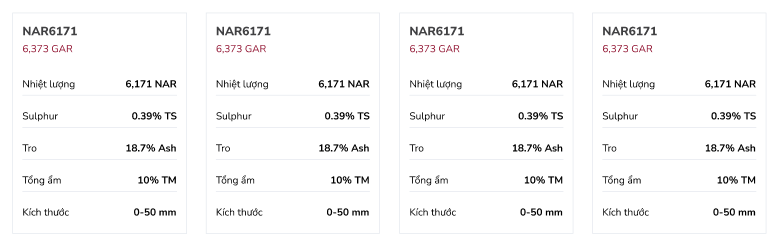

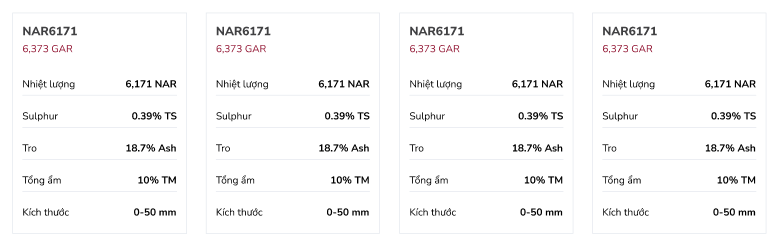

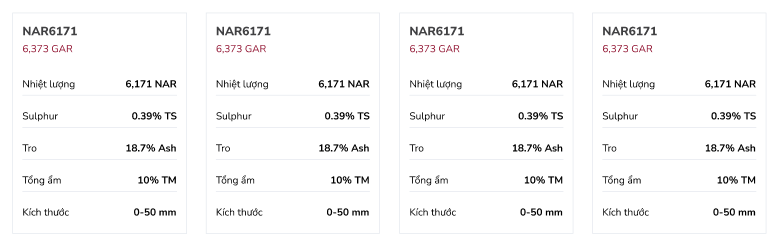

Product Features 4A7

Product Features 4A2

Product Features 4A3

Product Features 4A4

Product Features 4A5

Product Features 4A6

Product Features 4A7